Developing Integrated Multivariate Reliability Sensors

Introducing Integrated Multivariate Reliability Sensors

A United Nations panel held in 2008 concluded that “the way the world grows its food will have

to change radically to cope with growing population and climate change”. It is also worthy of

note that, we have been consuming more food than farmers have been producing for most of the

past decade. Researchers have concluded that to meet the rising food demand, we need another

green revolution technology, and we need it in half the time. It therefore means the incorporation

of new technologies, such as precision farming machines, agricultural robotics, technological

inheritance technique and cost-effective sensors into agricultural production system, not only

benefits productivity and environmental conditions, but it also improves the working conditions

of farm managers, laborers, and machinery operators as well as manufacturers that form the base

for optimum production, operation, and maintenance requirements. This is the essence of

developing an integrated multivariate reliability sensor-based system for CNC Machines,

Tractors and Agricultural Machinery for a cost-effective condition monitoring and maintenance

strategy towards a successful machined bearing-spindle assembly and agricultural production.

This strategy helps to guarantee the safety of operations, availability of machines, spare parts,

and related equipment for cultivation operation. The increased competition in agricultural

production demands maintenance improvement, that aims at the reduction of maintenance

expenditures, while keeping the safety of operations throughout the life cycle of a cnc machine

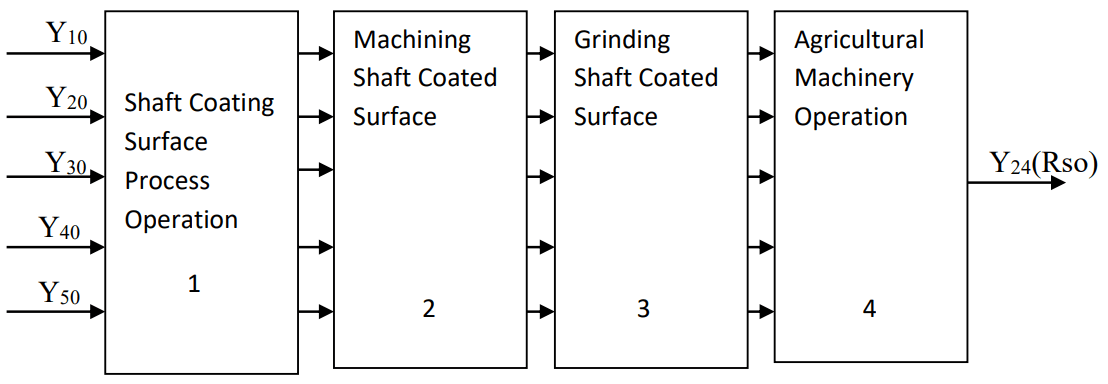

and agricultural machinery. The first step of this design consists of the concept of a design of

experiment and a mathematical multivariate regression model for the hard turning machining

process operations of hard alloy machine part surface quality parameters, (Yi) and the

optimization of the operating machining performance process using rotary cutting tool with

plasma spray conditions, (Xi) for wear and corrosion resistant applications as shown in Fig.1,3.

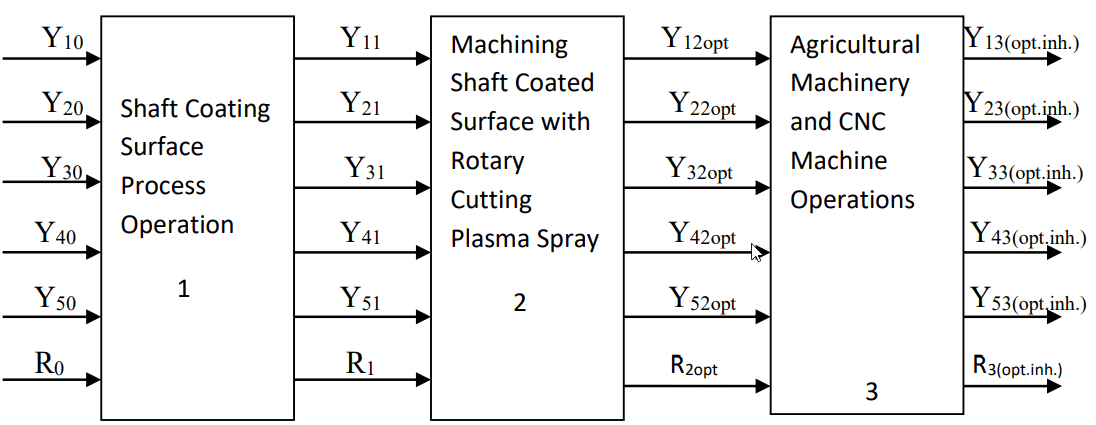

A multivariate regression model is used to describe the process as shown in a system of

equations [1]. The second step is generating the optimum (Yiopt.) and (Xiopt.) data for condition

monitoring, preventive, predictive and proactive maintenance strategies as well as design of an

integrated multivariate reliability sensor using a current signal as well as with the help of

technological inheritance network algorithm and analysis technique. The third step is the

relationship between the cnc bearing-spindle machines, cutting tool, workpiece, the hard-alloy

coating material and the working toll system for advanced/modern manufacturing technology,

tractors and agricultural machinery system with the application of an integrated multivariate

reliability sensor, tool holder, diagnostic and monitor with technological inheritance model.

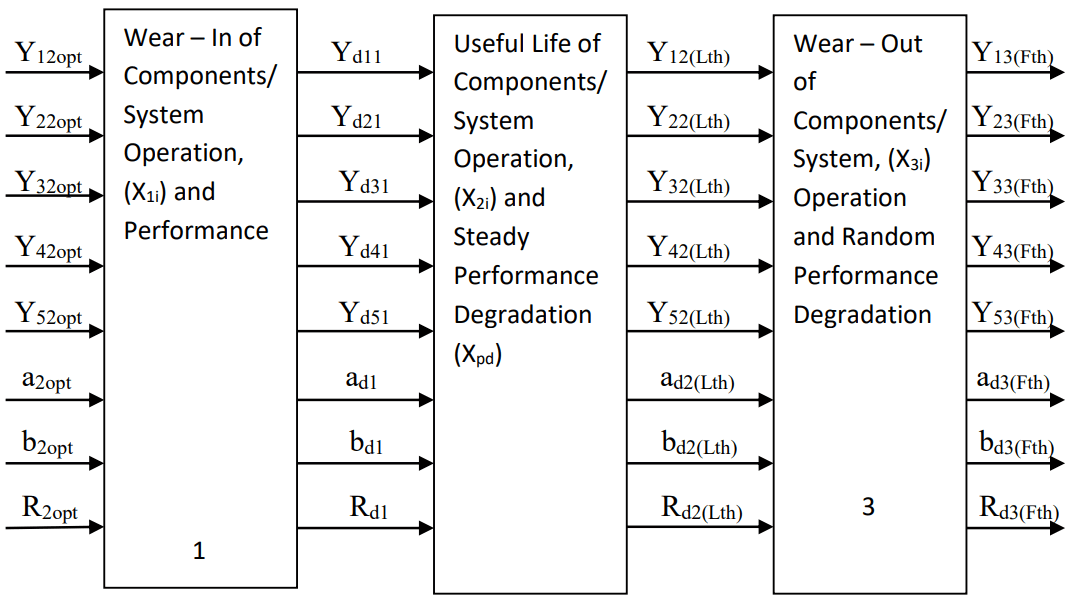

Technological Inheritance Technique is the transfer of the optimum bearing-spindle properties

from the initial operating stage of the cnc machine process performance to its final stage in a

turning machining technological system as well as within the cutting tool process operation and

in turn is transferred into agricultural productions. Technological inheritance model is used to

relate and integrate the cnc machine, workpiece, material and cutting tool system with tractor and

machinery system reliabilities. It is also used to design an integrated multivariate reliability

sensor-based tools, diagnostics and process condition monitors for a cost-effective adaptive

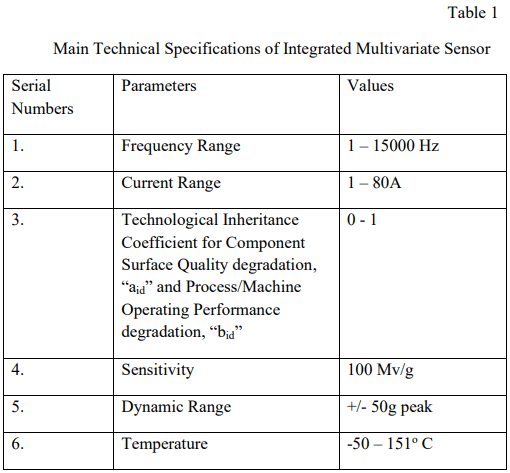

control and maintenance in cnc machines, tractors and agricultural machinery as seen in Figures

2, 4 and Table 1.

Y1- Surface Hardness

Y2- Surface Roughness

Y3- Surface Stress Concentration Factor

Y4- Surface Wavelength

Y5- Kinematic Coefficient

Y24(Rso) – Surface Roughness used for System Reliability

Figure1.The quality surface parameters and System Reliability of an existing technological chain

for producing hard-alloy coated shaft for wear and corrosion resistant application

Figure 2. Optimum shaft coated surface quality parameters and inherent System reliability for

wear and corrosion resistant applications with multivariate regression model

Where, Yi-1(opt) – Optimum surface quality properties of the previous operation (Shaft Coated

machined Surface with Rotary Cutting Plasma Spray)

Ydi – Component surface performance degradation of operating cnc machine and agricultural machinery

a(i-1opt) – Optimum technological inheritance coefficient of the previous operation from shaft coated

machined surface condition with rotary cutting plasma spray

adi – Technological inheritance coefficients of operating components in cnc machine and agricultural

machinery

bdi – Technological inheritance coefficients of operating process in cnc machine and agricultural

machinery

Ri-1(opt) – Optimum reliability of shaft coated machined surface with rotary cutting plasma spray from a

previous machining operation

Rdi – Operating reliability of cnc machine and agricultural machinery performance degradation

Lth – Useful life threshold

Fth – Failure threshold

Figure 3 Performance degradation path in cnc machines and agricultural machinery with Technological

Inheritance Model

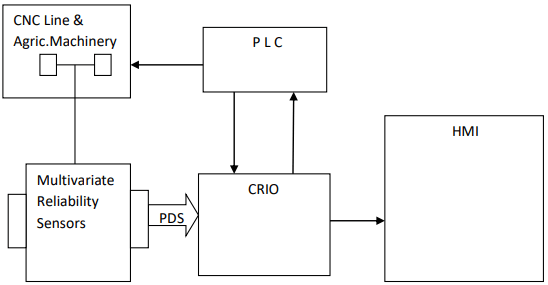

PDS – Performance Degradation Signal

CRIO – CompactRIO – Real-Time Controller (Reconfigurable I/O)

HMI – Human Machine Interface

PLC – Programmable Logic Controller

Figure 4 Schematic of the Set-Up of Performance Degradation Model Based Program and

Multivariate Reliability Sensors

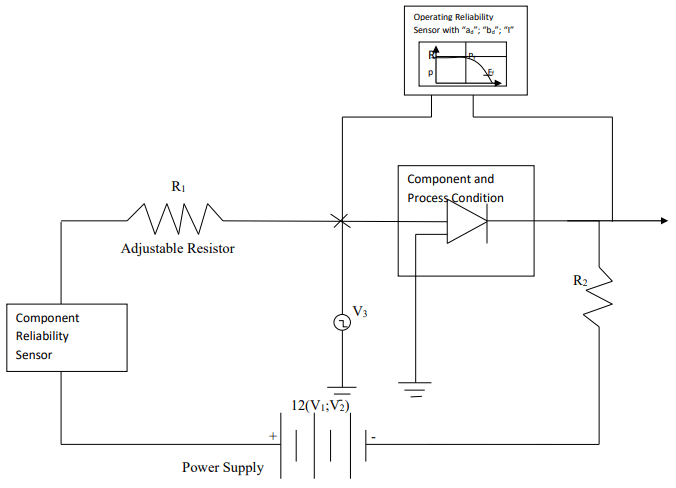

Figure 5 Multivariate Reliability Sensor circuit diagram for the performance degradation and

failure and Reliability tests of Components and Systems.

Benefits of an Operating Integrated Multivariate Reliability Monitor and Sensory Tool

Holder

1. An indirect online surface quality monitoring system approach is presented with a

wireless integrated multivariate reliability monitor and sensory tool holder.

2. A design of experiment is conducted to collect a hard-turning machining process and

coated spindle signals from the integrated multivariate reliability tool holder (IMRTH)

for wear and corrosion resistant applications.

3. Integrated Multivariate Reliability Sensor-based Monitor (IMRSM) is used to acquire

data for machine tool condition monitoring of multiple failure modes, identification of

failure root cause, performance degradation, operating reliability and cost-effective

selection of suitable condition-based maintenance strategy and diagnostics.

4. The sensor and model-based diagnostic can be effectively used in the diagnosis of

bearing faults of CNC Spindle through appropriate reliability measurement and life

prediction of CNC Spindle.

5. A time domain, frequency domain and time–frequency domain reliability and

performance degradation data, remaining time and failure features are extracted.

6. A surface quality, performance and reliability algorithm is adopted to identify the

different relevant features, which are evaluated through the surface quality and process

performance parameters for an overall reliability of machining processes.

7. Integrated Multivariate Reliability Sensor can be embedded and mounted on cnc

machines, agricultural machinery, monitors and motors.

8. Integrated Multivariate Reliability Sensor-based system is used to gather performance

degradation data to determine useful lifetime, potential and functional failure threshold

points as well as to perform reliability tests and design test equipment.

9. Integrated Multivariate Reliability Sensor-based system can be used to collect data at

intervals and continuously during real-time operations of machining and agricultural

production.

10. Integrated Multivariate Reliability Sensory tool provides the data for proactive scheduled

maintenance.

11. Integrated Multivariate Reliability Sensor-based system is a cost effective with higher

process performance, reliability, and productivity.

12. The design of Integrated Multivariate Reliability Sensor and model-based system is used

to determine the criticality of failures, parts, processes, tools, and equipment.

13. Integrated Multivariate Reliability Sensor and Model-based embedded system is used,

while the asset is working, which of course lessens the chances of disruption to normal

operations.

14. Integrated Multivariate Reliability Sensory system helps to improve reliability, while

minimizing unscheduled downtime due to catastrophic failure and requirements for

emergency spare parts.

15. Integrated Multivariate Reliability Sensor and Model-based System offers data for PM,

PdM, PrM, and Corrective actions to be scheduled at optimal time, while reducing total

cost of ownership and maximizing system reliability in manufacturing, agriculture,

aircraft and digital information technologies in businesses.

Proposal Development

It has been specified that, based on the results and works, the author introduced a bearing-spindle

machined surface quality parameter and turning machine cutting tool performance degradation

path with technological inheritance model for system reliability assessment and the development

of an integrated multivariate reliability sensor-based monitors, tool holders and diagnostics. The

development and application of an integrated multivariate reliability sensor-based system allows

for reliability analysis to be conducted to improve on detection systems, overcome critical

features revealed during operations, adaptive controls, and cost-effective maintenance

procedures. In particular, the work focuses on improving real-time performance degradation data

acquisition system, eliminates cnc machine and agricultural machinery hardware failures and

develops a dynamic failure – reliability threshold to increase detection sensitivity of the control

algorithm.

It is expected that these improvements will lead to more than 95% system reliability in

Manufacturing, Precision Agriculture, and Evidence Based Management in Businesses. In fact,

in this case, the savings associated with installation and maintenance investments, running costs

are so advantageous to justify the need for the development of an integrated multivariate

reliability sensor-based system of monitors, tool holders and diagnostics.

Conclusions

This work reports the development and application of online real-time component and machine

performance degradation path monitoring analysis for CNC and Agricultural Machinery, based

on time, frequency, and operating component reliability data with the help of technological

inheritance model. In order to conduct the analysis of the machine and machinery performance

degradation path, an integrated multivariate reliability sensor-based system with LabVIEW

software have been developed to measure the operating machined bearing-spindle surface quality

conditions and machine tool cutting process performance degradation data using electrical

current signal and technological inheritance coefficients was used. The machine characteristic

features from the performance degradation path may result in faults, cracks, imbalance,

unalignment, wear and other competing failures of the operating system are captured by the

sensor throughout the life cycle of the machine. The accurate results obtained validates the

effectiveness of the newly developed sensor-based system, since it can detect attenuation of

degradation data associated with faults and failures carry-over status from one phase to the other.

The transference of these features can be measured, monitored, analyzed and presented with the

new integrated multivariate reliability sensor-based system from the initial point to the final

stage within a specific period as well as from cnc machine performance degradation condition to

agricultural machinery conditions.

From an industrial and agricultural perspective, the relevance of this technological inheritance

network system and LabVIEW approach can be easily understood by considering the importance

of performance degradation method, degradation probe, reliability sensor, monitor, tool holder

and diagnostics in global markets, in component surface quality, in machine performance and the

reduction of global maintenance costs. This new quality, performance and reliability assessment

with technological inheritance method in fact provides an optimum trade-off between detection

accuracy, cost of installation and maintenance in order of magnitude is lower than vibration

method. The performance degradation and reliability analysis, using technological inheritance

model for cnc machines with integrated multivariate reliability sensor-based technique can be

used to standardize the system and improve component qualities and system reliability, making it

applicable and cost-effective in maintenance to all manufacturing processes and agricultural

operations. Embedding the newly designed multivariate reliability sensor-based program into cnc

machines and agricultural machinery maintenance and production system will benefit

productivity, serviceability, reliability and enhance the working conditions of farmers for a

sustainable development in manufacturing and agricultural industries.

Reference

1. Osarenren J.O, (2012) “Integrated Reliability: Condition Monitoring and Maintenance of

Equipment”, CRC Press, Florida, 479p.

Good https://is.gd/tpjNyL

Good https://is.gd/tpjNyL

Very good https://is.gd/N1ikS2

https://shorturl.fm/YvSxU

https://shorturl.fm/9fnIC

https://shorturl.fm/a0B2m

Get paid for every referral—sign up for our affiliate program now! https://shorturl.fm/Lv41D

Promote our products—get paid for every sale you generate! https://shorturl.fm/UhGrQ

Promote our products—get paid for every sale you generate! https://shorturl.fm/49gZV

https://shorturl.fm/DNUnh

https://shorturl.fm/X6uUq

https://shorturl.fm/wFmz6

https://shorturl.fm/Lc8sR

https://shorturl.fm/UCUHR

https://shorturl.fm/Z05c6

https://shorturl.fm/GxOtq

https://shorturl.fm/m6DUL

https://shorturl.fm/jowds

https://shorturl.fm/F1jiM

https://shorturl.fm/AD0hS

https://shorturl.fm/rJTmg

https://shorturl.fm/4PYSs

https://shorturl.fm/LoPNY

https://shorturl.fm/Br5kY

https://shorturl.fm/jQXdi

https://shorturl.fm/VqY5q

Become our partner now and start turning referrals into revenue!