DEVELOPING MULTIVARIATE RELIABILITY SENSOR

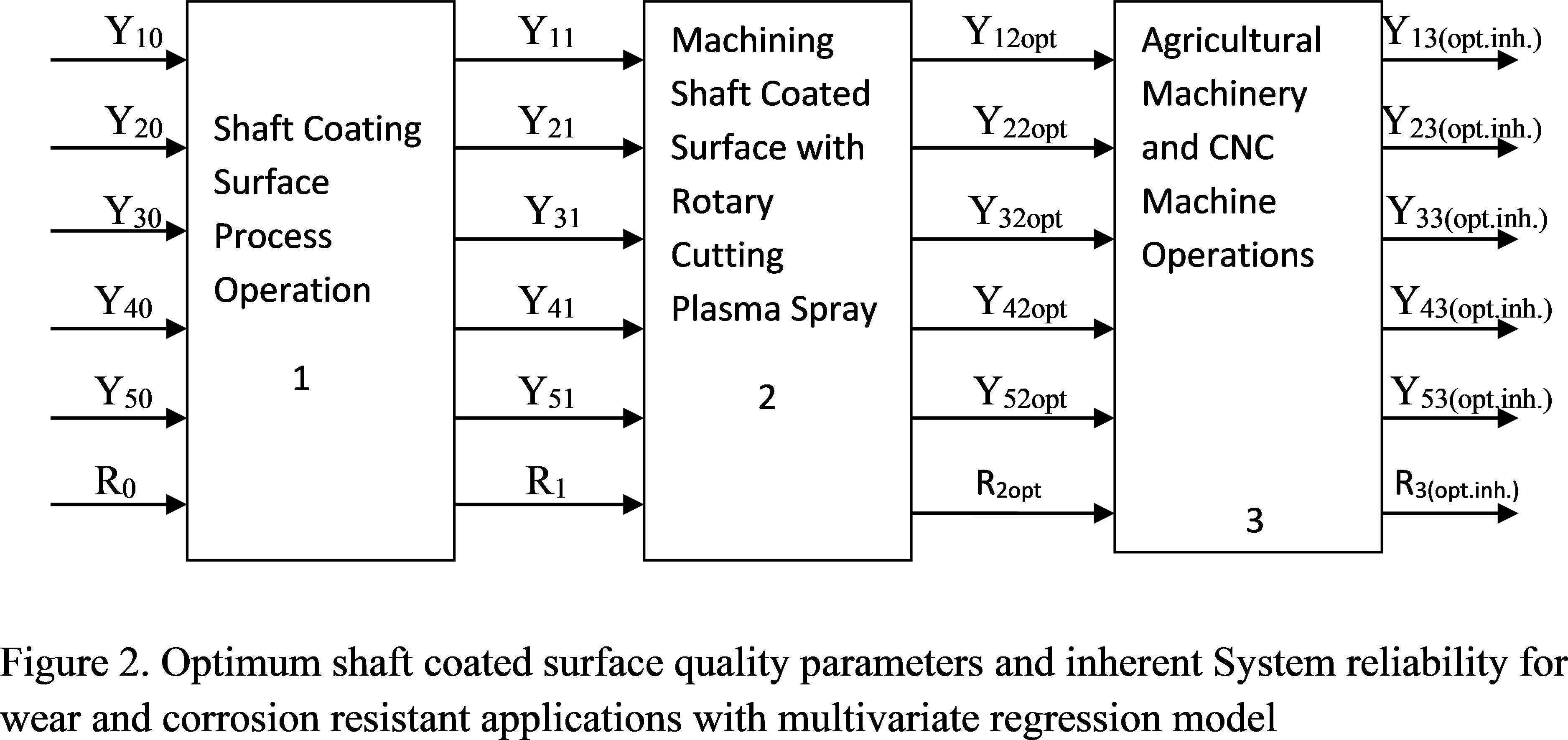

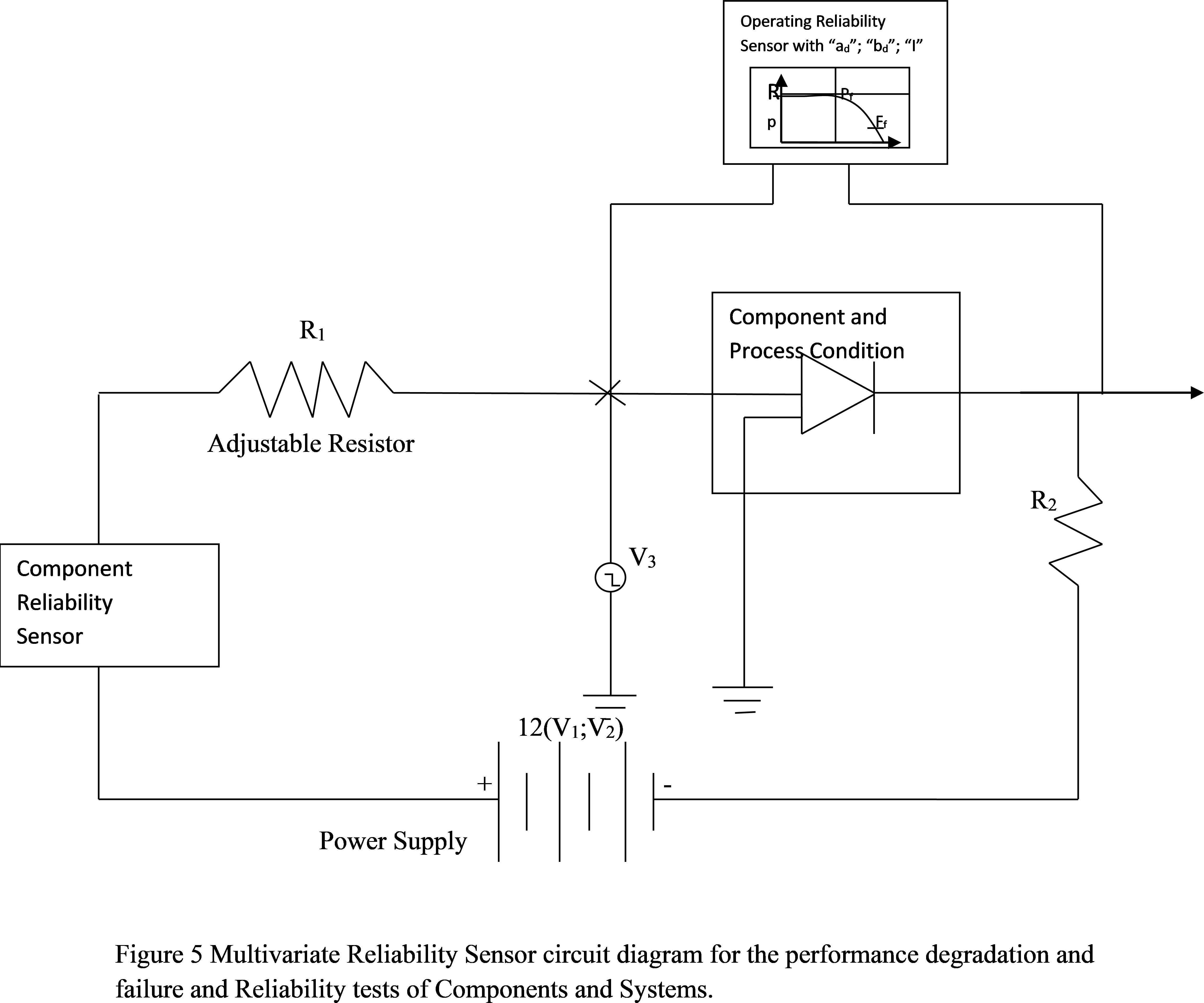

A United Nations panel held in 2008 concluded that “the way the world grows its food will have to change radically to cope with growing population and climate change”. It is also worthy of note that, we have been consuming more food than farmers have been producing for most of the past decade. Researchers have concluded that in order to meet the rising food demand, we need another green revolution technology and we need it in half the time. It therefore means the incorporation of new technologies, such as precision farming machines, agricultural robotics, technological inheritance technique and cost-effective sensors into agricultural production system, not only benefits productivity and environmental conditions, but it also improves the working conditions of farm managers, laborers and machinery operators as well as manufacturers that form the base for optimum production, operation and maintenance requirements. This is the essence of developing a multivariate reliability sensor for CNC Machines, Tractors and Agricultural Machinery with a cost-effective condition monitoring and maintenance strategy towards a successful agricultural production. This strategy helps to guarantee the safety of operations, availability of machines, spare parts and related equipment for cultivation operation. The increased competition in agricultural production demands maintenance improvement, that aims at the reduction of maintenance expenditures, while keeping the safety of operations throughout the life cycle of a cnc machine and agricultural machinery. The first step of this design consists of the concept of a mathematical multivariate regression model for the machining process operations of hard alloy machine part surface (Yi) and the optimization of the operating machining performance process using rotary cutting tool with plasma spray (Xi) for wear and corrosion resistant applications as shown in Fig.1,3. A multivariate regression model is used to describe the process as shown in a system of equations [1]. The second step is generating the optimum (Yiopt.) and (Xiopt.) data for condition monitoring, preventive, predictive and proactive maintenance strategies as well as design of multivariate reliability sensor from a current signal as well as with the help of technological inheritance technique. The third step is the relationship between the cnc machines, workpiece, material and the working toll system for advanced/modern manufacturing technology, tractors and agricultural machinery system with the application of a multivariate reliability sensor and technological inheritance model. Technological Inheritance Technique is the transfer of the properties of an object or component from the initial stage of technological process to its final stage in a technological system as well as within a process operation. Technological inheritance model is used to relate and integrate the cnc machine, workpiece, material and cutting tool system with tractor and machinery system. It is also used to design a multivariate reliability sensor and process condition monitors for a cost-effective maintenance in cnc machines, tractors and agricultural machinery as seen in Figures 2, 4 and Table 1.

Benefits of an Operating Multivariate Reliability Sensors

- Multivariate Reliability Sensor is used to acquire data for condition monitoring of multiple failure modes, identification of failure root cause, performance degradation, operating reliability and cost-effective selection of suitable condition-based maintenance strategy.

- Multivariate Reliability Sensor can be embedded and mounted on cnc machines and agricultural machinery.

- Multivariate Reliability Sensor is used to gather performance degradation data to determine useful lifetime, potential and functional failure threshold points as well as to perform reliability tests and design test equipment.

- Multivariate Reliability Sensor can be used to collect data at intervals and continuously.

- Multivariate Reliability Sensor provides the data for proactive scheduled maintenance.

- Multivariate Reliability Sensor is a cost saving, higher system performance and reliability.

- The design of Multivariate Reliability Sensor is model based, which helps to determine the criticality of failures, parts, processes and equipment.

- Multivariate Reliability Sensor is used, while the asset is working, which of course lessens the chances of disruption to normal operations.

- Multivariate Reliability Sensor helps to improve reliability, while minimizing unscheduled downtime due to catastrophic failure and requirements for emergency spare parts.

- Multivariate Reliability Sensor offers data for PM, PdM, PrM, and Corrective actions to be scheduled at optimal time, while reducing total cost of ownership and maximizing system reliability in manufacturing, agriculture, aircraft and other industries of the future.

Proposal Development

It has been specified that, based on the results and work a, the author introduced component and process performance degradation with technological inheritance model for system reliability assessment and the development of a multivariate reliability sensor. The development and application of multivariate reliability sensor will allow further analysis to be conducted in order to improve the detection system, overcoming critical features, revealed during operations. In particular, the work focuses on improving real-time performance degradation data acquisition system, to eliminate cnc machine and agricultural machinery hardware failures and developing a dynamic failure – reliability threshold, to increase detection sensitivity of the control algorithm.

It is expected that these improvements will lead to more than 90 – 95% system reliability in Manufacturing and Precision Agriculture. In fact, in this case, the savings associated with installation and maintenance investments, running costs are so advantageous to justify the need for the development of a multivariate reliability sensor.

Conclusions

This work reports the development and application of online real-time machine performance degradation path analysis for CNC and Agricultural Machinery, based on time, frequency and operating component reliability data with the help of technological inheritance model. In order to conduct the analysis of the machine and machinery performance degradation path, multivariate reliability sensors with LabVIEW have been developed to measure the operating component surface quality and process performance degradation data using electrical current signal and technological inheritance coefficients. The machine characteristic features from the performance degradation may result in faults, cracks, imbalance, unalignment, wear and other competing failures of the operating system can capture by the sensor throughout the life cycle the machine. The accurate results obtained validates the effectiveness of the newly developed sensor, since it can detect attenuation of degradation data associated with faults and failures carry-over status from one phase to the other. The transference of these features can be measured and monitored with the new multivariate reliability sensor from the initial point to the final stage within a specific period as well as from cnc machine performance degradation condition to agricultural machinery conditions.

From an industrial and agricultural perspective, the relevance of this technological inheritance and LabVIEW approach can be easily understood by considering the importance of performance degradation method, degradation probe and reliability sensor in global markets, in component surface quality, in machine performance and the reduction of global maintenance costs. This new reliability assessment with technological inheritance method in fact provides an optimum trade-off between detection accuracy, cost of installation and maintenance in order of magnitude lower than vibration method. The performance degradation and reliability analysis, using technological inheritance model for cnc machines with multivariate reliability sensors can be used to standardize the system and improve component qualities and system reliability, making it applicable and cost-effective in maintenance to all manufacturing processes and agricultural operations. Embedding the newly designed multivariate reliability sensor into cnc machines and agricultural machinery maintenance and production system will definitely benefits productivity, serviceability, reliability and also enhance the working conditions of farmers for a sustainable development in manufacturing and agricultural industries.

Reference

- Osarenren J.O, (2012) “Integrated Reliability: Condition Monitoring and Maintenance of Equipment”, CRC Press, Florida, 479p.

Leave a Reply