ENGINEERING QUESTIONS AND ANSWERS FOR GOOD SUCCESS LESSON: 101

THEME: The Principles and Terms relating to Simple Machines

DESCRIPTION: There are many technical terms used to describe the parts and functions of outdoor power equipment engines. Before diving into the basic principles of outdoor power equipment engine operations, it will be necessary to get familiar with these terms as they apply to things around us in everyday life.All of these terms will have a definite relationship in one way or the other to outdoor power equipment engine operation. There are a number of basic principles, one or more of which can be applied to all machines and mechanical applications. Engines used to power lawn mowers, garden tractors, chainsaws, rototillers and many other equipment are basically similar. They require the same basic intake of fuel and air to produce their desired results.

Engine principles can easily be applied to all machines and equipment applications by any undergraduate engineering student or high school students that are aspiring to be professionals. Understanding these terms and principles will definitely enhance the skills and grades of students as well as help them to know how to ask the right questions and answer them correctly.

Let’s look at some of these terms and principles:

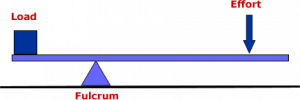

LEVER: The lever was probably the first mechanical application discovered by man. The lever is a simple method of increase the amount of force that can be exerted on an object as shown in (Fig. 1).

Figure 1 A lever Machine

When using this principle, a very heavy load can be lifted or moved with very little effort. It may be possible for a person to lift a thousand pounds but, with the help a lever the proper length and a fulcrum properly placed, this work could be easily accomplished.

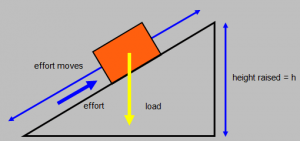

INCLINED PLANE: Another principle is the inclined plane. The inclined plane is similar in some ways to the lever. A load can easily be moved from one point to another by rolling it up an inclined slope as seen in Fig.2. If this load has a weight of several hundred pounds, it would be impossible to lift it from point to an upward point vertically. By rolling or pushing it up the slope, this work could easily be accomplished.

Figure 2 Inclined Plane

SCREW: The screw (Fig.3) operates on somewhat the same principle as the lever and the inclined plane. It operates on the principle of moving the load at an angle so that the applied force or effort must be moved a greater distance to move the load. The srew angle must move a long distance in order to raise or lower it. A common application of the screw is the car jack which allows you to raise a very heavy load with a little effort.

Figure 3 A Screw

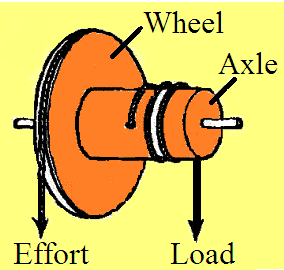

WHEEL AND AXLE: The wheel and axle (Fig.4) is more evident than most of the others. It transmits weight or load into rotary motion. A great amount of weight can be applied to a point on the axle and an object can be easily moved. The weight of the axle is transmitted to the wheel and converted into rotary motion for movement.

Figure 4 Wheel and Axle

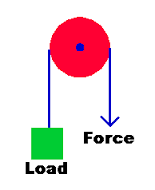

PULLEY: The pulley (Fig.5) permits moving weight that could be accomplished by lifting or pushing. By using different arrangement of pulleys, the lifting or pulling power can be increased several hundred times. A common example of this principle is the block and tackle used to lift heavy loads. Most automotive repair shops have a block and tackle they use for lifting engines from automobiles. This allows one man to lift the entire engine, weighing several hundred pounds, out of the car.

Figure 5 A Pulley

MECHANICAL ADVANTAGE: The five basic principles of the lever, inclined plane, screw, pulley and the wheel and axle are the basic actions that allows us to multiply the applied force. The number of times a force is multiplied is called the mechanical advantage. The basic principle of this action is that a force at the end of a lever produces a greater force at the short end. The amount of force applied at the long end of the lever is determined by the location of the fulcrum. If the fulcrum is moved the left, it will take greater applied force to move the load. If it were moved closer to the load, it would take less applied force.

FORCE: A force is pull or push exerted on an object in an attempt to change its condition. When a gas is heated, it expands and occupies more space. Gravity has a pull to bring things closer to the center of the earth. Magnetic poles attract or repels each other. These are all forces. They all tend to change the state of an object from its present state to another.

WORK: Work is the movement of an object or weight through a distance. Moving an object from one place to another requires work. Lifting a box or weight from the floor and placing on a shelf is work. The height of the shelf and the weight of the box determine the amount of work accomplished. From this we get the formula of:

WORK = FORCE X DISTANCE.

ENERGY: Energy is the ability to do work. This energy can be held in reserve or action. Potential energy is contained and not in action. A person at rest contains potential energy and when he begins to move this energy is the changed into kinetic energy.

GRAVITY: Gravity is one the four outside forces that have an effect on all simple machines. Gravity is the force that draws all bodies towards the center of the earth. The force of gravity gives us weight, it causes object to fall from the sky or roll down the hill. The center of the earth has an attraction drawing everything to this center. If it is above the earth, gravity has a pulling effect drawing it to the surface. Object readily moves down the hill because they are going towards the center of the earth. A weight dropped I a hole will go down because it is going towards the center of the earth.

INERTIA:

Static inertia is the tendency of an object to remain at rest. Without some outside force the body tends to remain at rest and not move.

Dynamic inertia is the tendency of an object to continue moving once it has been set in motion.

MOMENTUM: Momentum is the amount of motion of a moving object. Once you set an object in motion down the hill, you can see the principle of momentum. As the objects starts down the hill, it moves slowly, the it begins to pick up speed. The object is gaining momentum as it rolls down the hill.

RESISTANCE: Resistance is an opposing or retarding force. Two forces pulling away or pushing against each other is resistance. Resistance is also present when two forces oppose each other, such as two rough surfaces rubbing together. Resistance will often create friction. Various forms of resistance are often used in electrical components to retard the flow of electricity. Resistance is present in all engines caused by friction of the moving parts. Resistance is also present when an object is moving and has momentum.

TORQUE: Torque is twisting or turning force. The twisting or turning force is related to the turning or rotation force of an object. The term “torque” is used often when referring to the tightness of a bolt or nut and the turning force developed on an engine crankshaft.

FRICTION: Friction is the resistance to motion of two or more surfaces in contact with each other. Friction is present in some degree anytime two or more objects are moved against each other. Two smooth surfaces will create less friction than two rough surfaces. A piston sliding up and down in the cylinder creates friction. If no oil were present the friction would be very great, since oil reduces the amount of friction generated between two surfaces. Friction also causes heat to be generated, which is one reason an engine must have some method of cooling.

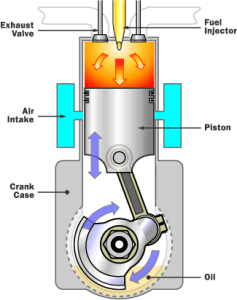

INTERNAL COMBUSTION ENGINE: An engine is a machine that converts heat into mechanical energy. There several methods in which heat energy can be converted into mechanical energy. As it relates to engines, there are generally considered to be internal (Fig.6) or external combustion engines.

Figure 6 An Internal Combustion Engine

To obtain combustion necessary to operate an engine, fuel is mixed with air and ignited to produce heat. The heat is then changed into mechanical energy. Fuel and air are mixed inside the cylinder and ignited by a spark plug.

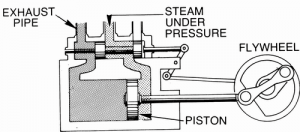

EXTERNAL COMBUSTION ENGINE: Heat is changed to mechanical energy by changing water into steam. Steam then forces its way into the cylinder to operate the piston. Instead of gas burning and expanding to force the piston back down as in an internal combustion engine, expanding steam forces the piston down. This is the basic principle of the steam engine, which is a external combustion engine as shown in Fig.7.

Figure 7 External Combustion Engine

COMPRESSION: Compression is a term that will be used in several ways in the description and function of an engine. Compression can be demonstrated with a spring. When the spring is being compressed, the pressure increases and the spring is reduced in length in the direction of the compression force. The action of engine valve springs is typical example of this type of spring compression..

Another application of compression is when liquids and gases also compressed in an engine operation. As the pressure is increased on the rod it brings the liquid under pressure in the jar. This type of compression is applied to the fuel-air mixture in the cylinder of an engine. When gases are compressed they are reduced in volume. A spring can be reduced in length and a gas will reduce in volume when brought under pressure, however, liquids have practically a zero compression ratio.

EXPANSION: Expansion is the ability to spread out or fill more space. A balloon without air occupies very little space. As it is filled with air, it begins to expand and occupy more space. This same principle is very important part of the function of an engine. Heat causes expansion when applied to metals. Heat generated by the engine causes the operating parts to expand. Parts must be adjusted and fitted so they will operate in their expanded condition after the engine heats up. An engine fitted with a piston that is too tight when cold, would expand and seize in the cylinder after the engines reaches its operating temperature.

CYCLE: A Cycle is a complete series of events occurring in the same sequence.

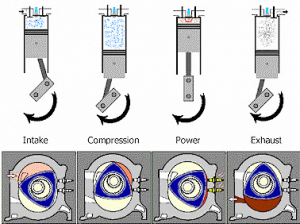

A 4 – cycle internal combustion engine also has a series of four cycles. In order for this engine to complete one series of events it goes through the Intake, Combustion, Power and Exhaust stroke. After the exhaust stroke is complete, it repeats the cycle again and continues repeating until the engine stops.

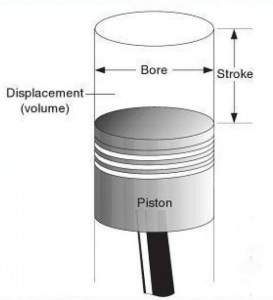

DISPLACEMENT: Engine displacement is defined as the volume of the space through which a piston travels during a single stroke in an engine.

Figure 8 Displacement

Top Dead Center, known as TDC, is the furthest point of upward travel of the piston in the cylinder.

Bottom Dead Center, known as BDC is the lowest point of downward travel of the piston in the cylinder. The space in the cylinder between TDC and BDC is known as Displacement. Piston Displacement is expressed in cubic inches (ci), cubic centimeters (cc), or liters (L).

BORE-STROKE: Piston stroke is the distance the piston travels within the length of the cylinder. It is the distance between the maximum up-stroke and the maximum down-stroke. The Bore is the diameter of the cylinder. The combination of the bore diameter and the length of the piston stroke determines the cubic inch displacement of the engine.

PARTS OF THE PISTON: The piston is the sliding part that rides up and down inside the engine cylinder. Most pistons have three Rings, that seal the gap between the cylinder wall and the piston. The piston has lands. These are the metal ridges between the ring grooves. The piston skirt is the low hollow part of the piston. The skirt keeps the piston sliding straight up and down within the cylinder.

SLEEVE: The sleeve is the hard, cylindrical insert installed inside the cylinder. The sleeve is inserted inside the cylinder with a very tight press fit and is made of a harder metal than the cylinder wall. The use of a sleeve permits the cylinder to be made of different metals that otherwise would not be compatible with the hard metal of the rings. When sleeves are used the cylinder block is often made of a much softer metal.

PORT: A port is an opening in a part through which gases or liquids can flow. Fuel and air mixture enters through the intake port. The exhaust port is through which the spent gases escape after combustion. When the piston is in the up position both of these ports are closed.

THROW AND THRUST: Throw is the distance between the center of the crankshaft and the center of the crankpin.

Thrust is the force directed along side the axis of a part. As the piston is forced down the thrust moves along through the connecting rod to the crankshaft. This thrust causes the crankshaft to turn.

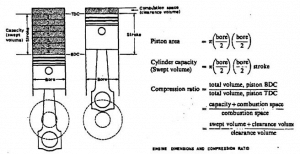

COMPRESSION RATIO: There are four basic requirements necessary to make an engine operate. These things are air, fuel, ignition and compression. All three of these must be present and in the proper proportion or an engine will not operate properly. By compressing the fuel and the air mixture up into one end of the cylinder more power can be obtained from the mixture. The amount the fuel and air mixture is reduced in volume is called the compression ratio.

Figure 9 Compression Ratio

BLOW-BY: When the air-fuel mixture is ignited in an internal combustion engine, an explosion takes place that drives the piston back down into the cylinder to deliver power to the crankshaft. If the area in which this explosion takes place is not tight enough, power will be lost. The piston should have a tight fit between the rings and the cylinder wall. If this seal is not tight, much of the explosive force will be lost through this area.

BACK-FIRE: Back-fire occurs when the fuel – air mixture ignites before it is supposed to. This is usually due to improper timing. If the valve does not close at the proper time, the fuel – air mixture may ignite in the intake manifold.

Back-fire can also occur in the exhaust system due to incorrect timing or poor combustion. Regardless of its source, backfire is a sign of poor engine operation.

RECIPROCATING AND ROTARY MOTION: An engine first produces reciprocating motion by the action of burning fuel expansion driving the piston up and down in the cylinder. This action is the turned into rotary motion. As the piston moves down, it applies a thrust to the crankshaft which turns in a circular motion.

Figure 10 Reciprocating and Rotary Motion

HOW TO TURN YOUR LEARNING AND PRACTICE INTO GOOD SUCCESS

To get the most from this lesson notes, you need to first of all read through it to get a general idea of what it covers. Then, go back and read it again – this time, read slowly, topic by topic.

As you read, don’t worry about “memorizing” facts or wording. All you need to do is form an understanding of the principle or procedure involved and you will never forget what you have learnt. visit: www.integratedconsulting.org

E-MAIL: info@integratedconsulting.org

Leave a Reply