ENGINEERING QUESTIONS AND ANSWERS PROGRAM FOR GOOD SUCCESS LESSON: 103

THEME: The Introduction to Outdoor Power Equipment Engine Service

DESCRIPTION: Engines used to power lawn mowers, garden tractors, chainsaws, rototillers and many other equipment are basically similar. They require the same basic intake of fuel and air to produce their desired results. They are known as Internal Combustion Reciprocating Engines. To make OPEengines stand up under the heavy demands they are subjected to, manufacturers provide them with larger crankshafts, main bearings and more oil supplies per horsepower than those in automotive engines. Most engines are built to government specifications, which provide that the engine must be designed to operate under full load at its top speed for 1,000 hours. Some have been able to run longer. A thousand hours is usually considered to be a long life OPE engines operated on an irregular basis. The engine cares and operations are needed and should be well studied by any undergraduate engineering student or high school students that are aspiring to become professionals. Understanding OPE engine services will definitely enhance the skills and grades of students.

Let’s therefore study some lesson notes that will lead us to good success and great professionalism as well as enhance the skills and grades of students.

Let’s study some of these lesson notes:

THE PROBLEMS WITH OUTDOOR POWER EQUIPMENT ENGINES

Their problems of not working properly are often due to lack of understanding of how the engine works and how it should be cared for and maintained. Most engine troubles are generally due to lack of proper service, operation, maintenance and repair.

You should first examine the conditions under which the engine operates. Most of the engines are designed to operate continuously at near top speed to prevent overload. All functions must be operating at top efficiency at all times. There is generally very little power to spare so every bit of it must be put use.

ENGINE ABUSE

The speed of the average outdoor power equipment engines may be sometimes around 3600 RPM. This equivalent to an automobile operating at over 80 miles per hour. This high RPM is generally the continuous operating speed when being used. Chainsaw, string trimmers and air/leaf blower engines operate at 4,000 – 10,000 RPM to develop the required power.

During operation, outdoor engines are often subjected to much abuse, overload and over-speeding. They are sometimes operated near ground level where dirt and dust are likely to get into their working parts. Often they not serviced and cleaned properly causing rapid wear. Few of these engines receive the proper servicing and maintenance that is given to other types of engines.

If you understand outdoor power equipment engines, you can apply this same basic knowledge to larger engines such as automobiles and tractors.

COMMON CAUSES OF OPERATING TROUBLES

Allowing dirt or foreign matter to enter the engine is one of the most common causes of engine failure. Lawn mowers and other equipment operating near the ground consistently have trouble from dirt entering the engine or carburetor. Failure to check the oil level in the crankcase is one of the main trouble areas of the 4 – Cycle engine. If the engine oil level is low it will not lubricate properly and can cause minor and often severe damage.

Overloading the engine will cause early breakdown and running the engine too fast will shorten the life of the engine. Most of OPE engines are equipped with governors to control their speed for most efficient and safe operation. Often the governor can be changed or disconnected. This will allow the engine to operate at a higher RPM, but it will shorten the life of the engine considerably. Always make sure you read the Operator’s Manual that comes with the engine and follow the instructions.

ENGINE IDENTIFICATION

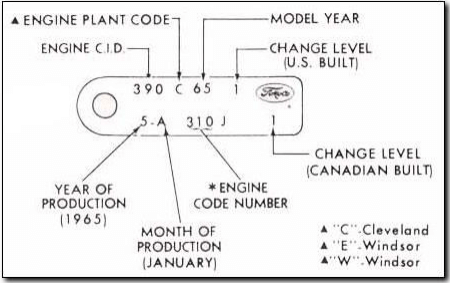

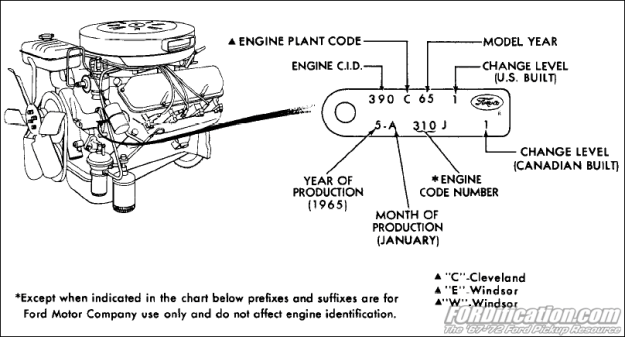

Engine operates on the principle of both the fuel and lubricating oil being mixed together. The 4 – Cycle burns gasoline as fuel and has a separate oil system to lubricate the engine. To get the proper parts for engine repair, it is necessary to know exactly what kind of engine, the parts are needed for. There are many different manufacturers, engines sizes and other specifications that must be taken into consideration in order to get the right part. Parts may sometimes be interchangeable with different brand names. (Fig.1,2)

Figure 1 Engine Identification

Figure 2 Engine Identification in Ford Motor Company

When engines come from the factory, they have the necessary information to identify them and order replacement parts on a nameplate. First we will need to know the name of the engine. This will generally be the name of the manufacturer but could also be the brand name under which the engine is sold. Next is the model numbers of the engine. This number will usually give a clue as to the horsepower of the engine. Some model numbers refer to other information such as type of crankshaft and accessories or modifications. As a further check, the serial number is necessary to insure the proper replacement part. The serial number tells the sequence in which the engine came off the assembly line.

The specification number refers to the different designs requested by the equipment manufacturers that the engines are to be used with. The size is generally the bore and stroke of piston or horsepower. The RPM is the rated engine operating speed. The type and specification information is included in the model and serial number on most engines.

USER SERVICING OF OPE ENGINES

It is a known fact that if you expect to get trouble free service from a engine it must be serviced regularly. When this should be done varies with some manufacturers recommendations; the operating conditions under which the engine is used and the type of work it is to perform. There are three times period when all OPE engines should be checked by the user or referred to the repairman. Before each operation, the operator should the crankcase oil level in 4 – Cycle engines and fill the fuel tank with clean, fresh, unleaded regular gasoline. Each 25 hours of use the crankcase oil should be changed on 4 – Cycle engines. If the engine is operating under extremely dirty conditions, this 25 hour inspection should be done more frequently.

An annual inspection should be done by the OPE engine repairman. Customers will save money in the long run by bringing their engines in at least once a year for annual cleaning, inspection and tune-up. This would include fuel filters, crankcase breather, points and condenser, new spark plugs and other minor adjustments.

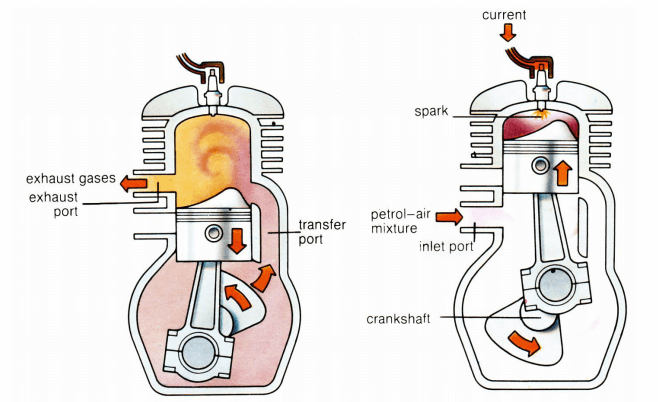

2 – CYCLE AND 4 – CYCLE IDENTIFICATION

From the outward appearance of an engine, it may sometimes be difficult to determine whether it is 2 – Cycle or 4 – Cycle. There are three quick methods you can use to identify the engine. First check for an oil filter plug or cap located toward the lower part of the engine. If an oil filler plug is present the engine is 4 – Cycle. If the nameplate gives oil specifications for crankcase oil the engine is 4 – Cycle. If it gives information on mixing oil and fuel, the engine is 2 – cycle. (Fig.3,4)

Figure 3 2 – Cycle Engine

Figure 4. 4 – Cycle Engine

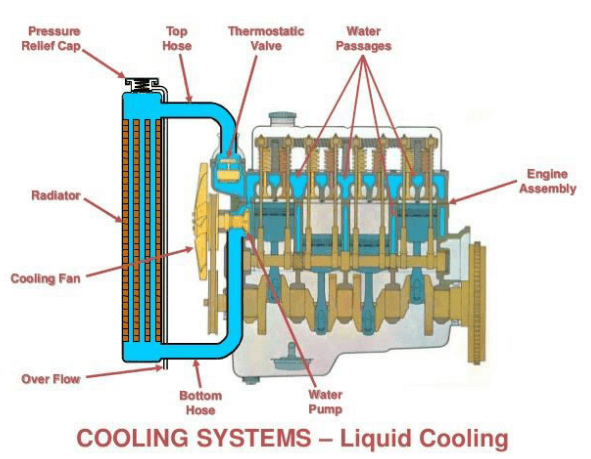

HOW OPE ENGINES ARE COOLED

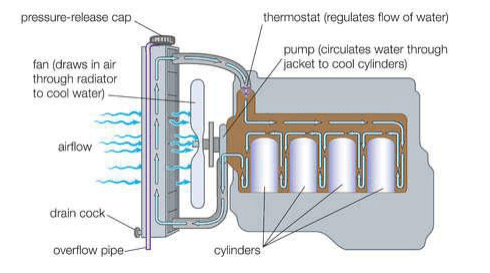

Most OPE engines, particularly the ones used on lawn mowers, motorcycles and garden tractors are air cooled. Most major brand outboard motors are water cooled engines. However, in recent years, some outboard engines are air cooled. An air cooled engine depends on the flow of air around the engine to take away the heat generated by the moving parts of the engine. In order for this heat to dissipate it is necessary that the engine be kept clean and have a constant movement of air. (Fig.5,6)

Figure 5 Engine Liquid Cooling System

Figure 6 Engine Air Cooling System

CONDUCTION AND CONVECTION

Conduction is a term used to describe the transfer of heat through a solid conductor such a the cylinder wall of an engine. Convection is the term used to describe the transfer of heat through the movement of gases or air. When air is heated it becomes less dense and raises. Other cool air then moves in to replace it. Forced convection is used to speed up the cooling process. By the addition of a fan and baffles the air flow is increased. Cooler air is forced past the cooling fins and removes the hot air from around the engine.

This forced convection is accomplished by a flywheel blower forcing air past the cylinder wall and cooling fins. It is directed around the cylinder by the cylinder baffles. Air baffles are not necessary on water cooled engines. Water has a much higher efficiency than air to dissipate heat from an engine.

IMPORTANCE OF CLEANING

One of the most important things in getting maximum engine life from an OPE engine is keeping it clean. Engine operators will often vary in using the proper fuel mixture, oil change and other regular maintenance but overlook keeping the engine clean. Overheating is often caused by dirt and grime on the outside of the engine and by a clogged or restricted exhaust system.

Dirt and grime are very poor conductors of heat and will heat in the engine. They act just like an insulator and will not allow the heat to dissipate. A clogged muffler will also cause an engine to overheat. It creates a back pressure in the cylinder and restricts the hot gases from escaping. Since onethird of engine heat is given off through the exhaust system, this can cause the engine to overheat very quickly.

If dirt is allowed to enter inside the engine, it can cause rapid wear on all moving parts. In addition to being an insulator, dirt also acts as an abrasive and causes excessive wear on all moving parts. Dirt can when you check the crankcase oil level and it can get into the air cleaner assembly when the filter is removed. One big advantage of cleaning an engine regularly is to reveal any hidden weak points or defeats.

CLEANING TOOLS AND MATERIALS

Most of the well operated shops will have a place set aside just for the cleaning operation. It is best to have separate set of tools and equipment set aside in this area just for cleaning operation. For most OPE engines the following tools and equipment should be adequate for the cleaning operation:

- Slot-head screwdriver, 6-inch.

- Philips head screwdriver, 6-inch

- Socket Set – including 3/8″, 7/16″, ½”, 5/8″, and 9/16″ sockets.

- Open end wrenches, same size.

- Wire brush.

- Solvent container, 2 – gallon

- Paint brush, ½” to 2″

- Water hose and Nozzle.

- Putty Knife, ¾”.

- Small stiff brush, such as toothbrush.

- Commercial solvent degreaser

- Hand sprayer

- Cleaning pan, 8″ x 4″ x 3″ deep.

A fire extinguisher is a must in any engine repair shop. The presence of fuel always presents the possibility of fire. The extinguisher should be of the dry, carbon dioxide, or foam type. These three types of fire extinguishers are most effective for gasoline or other petroleum-type fires.

An air compressor is one of the handiest pieces of equipment in most shop. It is very helpful in removing dirt from hard-to-reach places.

ENGINE OPERATION

The OPE gasoline engine is known as an internal combustion engine. The engine gets its energy or power to drive the crankshaft by controlled burning of gases generated within the engine itself. The basic principle of internal combustion engine is such that, the cylinder contains a piston, which is forced to make a downward travel because of the fuel and air mixture igniting in the top of the cylinder.

The fuel and air mixture is brought under pressure by the piston and then ignited by the spark plug. This controlled burn forces the piston back down. The piston itself always travels in a straight line. The top part of the rod is connected to piston and the lower part is connected to the crankshaft. The crankshaft is offset at the point the rod is connected to it. As the piston moves up and down it changes the straight line motion of the piston to a rotary motion on the crankshaft.

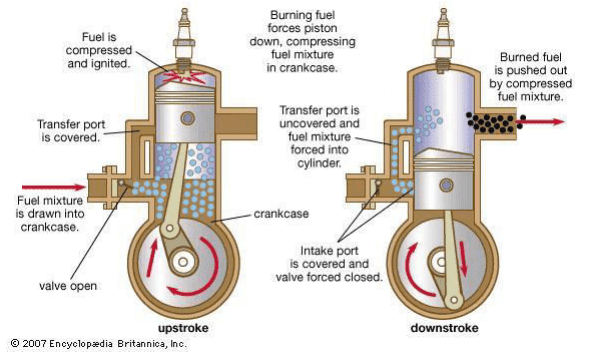

In order to an engine run continuously there are four different events that must take place. Failure of any of the events will not complete the series and the engine will not run. These four events are called strokes or cycles. (Fig,7)

Figure 7 Engine Operation of a 4 – Stroke Internal Combustion

Figure 8 Engine Operation of a 2 – Stroke Internal Combustion

Intake is the first of the four steps. The piston travelling on the down or intake stroke. As it travels down, a vacuum is created, drawing fuel and air mixture into the cylinder. The valve is open allowing fuel and air to enter.

Compression of the fuel – air mixture is the second event in the cycle. The piston traveling up and both intake and exhaust valves are closed. As the piston moves up, it begins to compress the fuel and air mixture contained in an area. As the fuel and air is compressed it becomes highly combustible. With both valves closed the fuel and air mixture cannot escape.

The next event is the Power stroke. As the piston reaches the top and has the fuel and air mixture under compression, the spark plug fires and ignites the fuel and air mixture. The expanding burning mixture moves the piston in the downward direction with both valves still closed.

The last event to take place is the Exhaust stroke. After the piston reaches the bottom of the stroke it begins moving upward again. At this point the exhaust valve is open and allow the burned gases to escape. The intake valve is closed. The completion of this series of event is called the engine cycle. The full travel of the piston in one direction, either toward or away from the top of the cylinder, is called a stroke.

Some engines complete a cycle during one revolution of the crankshaft. This would be two strokes of the piston. These engines are called 2 – cycle engines (Fig.8). Others are designed to require two revolutions of the crankshaft or four strokes of the piston.

HOW TO TURN YOUR LEARNING AND PRACTICE INTO GOOD SUCCESS

To get the most from this lesson notes, you need to first of all read through it to get a general idea of what it covers. Then, go back and read it again – this time, read slowly, topic by topic.

As you read, don’t worry about “memorizing” facts or wording. All you need to do is form an understanding of the principle or procedure involved and you will never forget what you have learnt. visit: www.integratedconsulting.org

E-MAIL: info@integratedconsulting.org

Leave a Reply